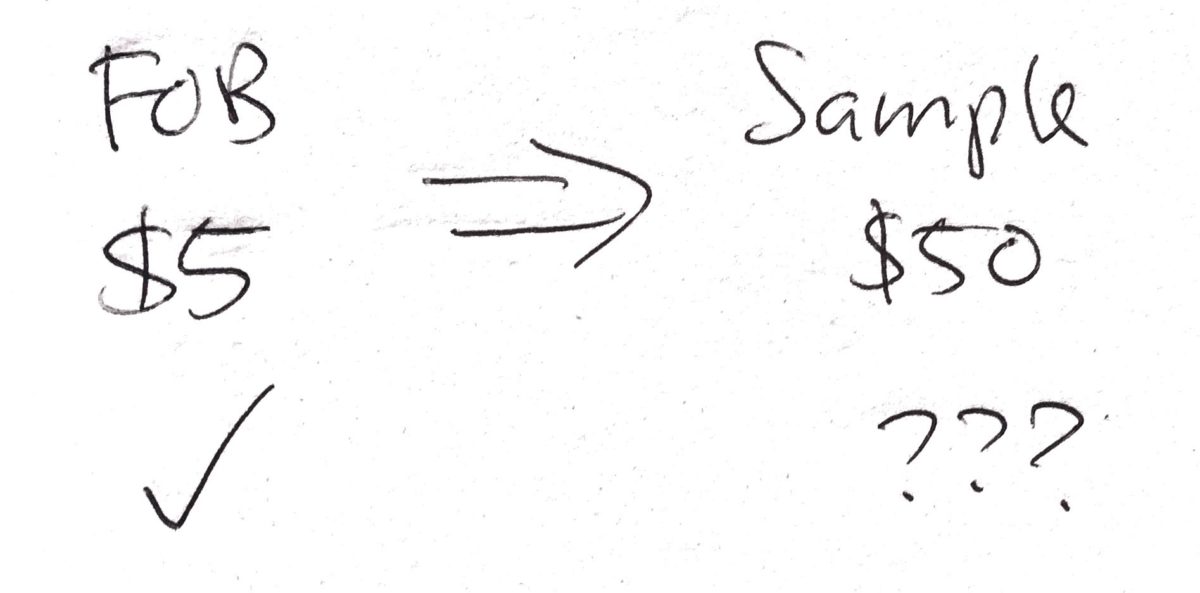

Why are factory samples more expensive than their FOB quotations? If they quoted me $5.00 FOB then why is the sample fee $50? While you may think that they are trying to rip you off, there are a couple of reasons behind this:

- Higher labor and handling fees to make one unit and prepare it for shipment vs economies of scale for a large order

- Quick way to filter out the non-serious buyers – 80/20 rule

- Company policies

Factories are configured to churn out large orders of hundreds or thousands of units or more. Normally the larger the order you give them, the happier they are. This is because their entire supply chain and production is configured to produce large quantities. From the purchase of the raw materials and components in bulk, to the costs of moving them to the factory, to the labor costs of the workers on the assembly line, rent, utility costs, storage, quality control, packaging, shipping, etc. Everything is configured for economies of scale. As a general rule of thumb, the larger the order, the more their cost savings on a per unit basis, and the lower the price they can offer you.

On the other hand, before you place your purchase order you probably want to ask your supplier for a couple samples. What happens next? First of all they may not necessarily have an item in stock. For example if you want to order a custom designed t-shirt from a factory they may not have the fabric or trim in stock. So they would have to purchase the raw materials and components at a higher cost because of such a small quantity. Instead of paying bulk wholesale costs from their suppliers, the factory may have to pay RETAIL costs for fabric, buttons, trim, and other components. Then when it comes to actually making a sample, often times they will have to make it by hand and not in the typical production line process. Factory equipment is not configured to cut, sew, dye, or glue just one t-shirt. You may need at least 50 yards of fabric to even start the machine for one production run. Finally the administrative costs of their staff to communicate with you the sample details, prepare invoices, receive payment, and prepare it for an international shipment all adds to the cost of the sample. So it’s not uncommon for the factory to offer an item for FOB $5 and ask for $50 for a sample.

Secondly if this is the first time potentially doing business together, the factory needs to filter out non-serious buyers. Just as you are screening suppliers looking for one that makes the right product, offers good quality, competitive pricing, and is trustworthy enough to do business with, the supplier is evaluating your in similar ways. Do they have experience in this industry or are they new? Does this person seem credible? Are they willing to purchase decent volumes are they constantly haggling over MOQ?

If you put yourself in the factory’s shoes, one of the best ways to screen out the riff-raff is by testing if they are willing to pay for sample costs. 80/20 rule – this will screen out many of the less serious or less experienced buyers and leave you with the 20% who are more likely to be a business partner.

Quick history lesson, when Chinese factories first started exporting, many offered free samples to prospective clients in hopes of capturing their business. However many unscrupulous individuals learned of their generosity and began taking advantage of them. Some abused this and requested many many samples for free so the factories learned the hard way. As they say “Fool me once shame on you, fool me twice shame on me.” Thus sample fees became commonplace.

A third reason is that some suppliers may have strict company policies enforcing sample fees. This really depends on the company and their rules.

But there are ways to reduce or eliminate sample fees. One of the best ways is to establish trust with the supplier and make them want to do business with you. By building a relationship or “guan xi” you can make them actually want to give you the product to test. Let’s role play for a minute. If you were a factory boss and a large buyer like Walmart came up to you and was interested in your t-shirts, would you charge a $50 sample fee? NO! You would gladly give them your t-shirts in every style and color you had for FREE so that they can evaluate them and place a huge order that will keep your factory busy for months!

The same strategy applies to your sourcing. If you establish yourself as a trusted buyer with experience and potential to place large orders, the factory may be motivated to not only offer you samples for free, but also better pricing, faster responses, and be more willing to customize your product.