My name is Gary and I’m an American based in Shanghai and have been sourcing from China since 2008. I’ve sourced a variety of products for clients ranging from industrial products, solar energy products, exercise equipment, auto parts, and more. I’ve worked with and visited hundreds of suppliers across China, big and small, and I’ve seen the good, the bad, and the ugly.

My name is Gary and I’m an American based in Shanghai and have been sourcing from China since 2008. I’ve sourced a variety of products for clients ranging from industrial products, solar energy products, exercise equipment, auto parts, and more. I’ve worked with and visited hundreds of suppliers across China, big and small, and I’ve seen the good, the bad, and the ugly.

I’m offering general advice to help you not get scammed when sourcing from Chinese suppliers on Alibaba. I assume you know the basics of using Alibaba so I’ve focused on the strategy encompassing the process from initial request for quotation to negotiating prices and terms, to requesting samples and evaluating the factory, to placing the initial order and arranging a production inspection. Also included are some best practices to follow and dirty tricks to be aware of to help you save time and headaches later.

1) Product

Your goal is to make sure the supplier understands your product specifications and the level of quality.

Define the product that you’re looking for. To save time from going back and forth with the supplier as well as to organise your thoughts, spend 15 minutes to put together a Request for Quotation (RFQ) that you will send to the prospective suppliers. Here’s a template you can use:

Product Name – WIDGET ABC

Detailed Description

– Exact Product Name

– Size/Dimension

– Material and Grade/Quality Standard (for example 316L Stainless Steel)

– Application

– Packaging/Packing

– Any other special factors you care about

Quantity Required

Annual Purchase Volume (estimate is OK)

Target Unit price

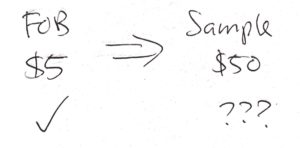

Shipping Terms: FOB port (for sea freight) or EXW Factory (normally for air freight)

Destination Port

2) Evaluation

As you send the RFQ to suppliers and get their replies, you will evaluate them not just on price but also responsiveness and service. Think of it as a dating game – e.g. looks will be the first impression but are they down to earth, or flaky, or materialistic, etc? Some factors to consider include:

-Are they responsive?

-Do they answer your specific questions or do they give a generic auto response?

-Do they provide actual product photos or are they copied from somewhere else?

Best practice: Call them over Skype to follow up. Find out more about their company background, factory and production information, their main products, and export markets. Some questions to ask include:

-Do they manufacture these products themselves or are they a trading company?

Trading companies are middlemen. In the best case scenario they have better english skills and can make it easier to communication if you don’t speak Chinese. Also they may (or may not) have access to better suppliers which you may not easily find on your own. Also they may be able to negotiate lower minimum order quantities from the supplier because they have bulk purchasing power.

However there are some downsides which include higher prices due to their margins, lack of transparency as they may not reveal the actual factory, and the risk of getting scammed since they can disappear overnight. There are instances of unscrupulous suppliers shipping out a container of dirt.

Be aware that the supply chain varies by industry. For example industrial product manufacturers typically purchase components and in fact only assemble them. Unless you are dealing with a huge player, it’s rare to find a fully vertically integrated factory. For instance, even Apple’s contract manufacturer Foxconn does not manufacturer all parts themselves. They purchase from component suppliers – for instance displays from Japan Display Inc, chips from Broadcom and Qualcomm, batteries from LG, etc.

Also it’s common practice for factories to establish their own trading companies in order to export. Do you homework and find out.

-Which countries do they export to?

This is very important because you want gauge the quality of their product to fit your customer’s’ needs. For example Yiwu has a famous export mart. The suppliers here offer mainly mediocre to low quality product. They are usually the domestic market and will quote in RMB. They may not have export licenses so you will need to either have to export yourself (documentation, arrange freight forwarder, customs clearance, etc) or go through a trading company. If these suppliers do export, they mainly export to African and Middle Eastern countries who’s markets prioritize lower prices and LOWER QUALITY than factories that export primarily to North America and Europe. If you are going to sell this product in the US or Western Europe this may not a good idea. Don’t try to fit a square peg in a round hole. You will bound to have struggles trying to sell product from a lower quality factory to a higher end market unless you are selling them to the 99cent only store.

3) Negotations

There a saying in Chinese: “??????” “Yi fen qian Yi fen huo” – You get what you pay for

In China you get what you pay for. The cheapest product will be low quality. This carries the most risk of suppliers cutting corners and using inferior product (or substitutes). As you compare suppliers and quotations you will get a feel for the market price as well as the professionalism, responsiveness, production, and export capabilities of each supplier. You should make a decision based on these variables as well as the X-factor which is your level of comfort and trust with the supplier. Successful importers build long term relationships with their suppliers. Think of it as a marriage where both parties are invested in each other.

???? “Huo bi san jia” – Compare at least 3 suppliers

Depending on your time, budget, manpower, and requirements never just talk to one supplier. Request quotations from at least 5-10 suppliers to get an idea about the pricing, compare specifications, factory sizes, and also get an idea of where the product production is clustered. Large corporations have entire sourcing and procurement teams that audit hundreds of suppliers. If you are serious about sourcing you must do your due diligence. Front-load your work to reduce risks and headaches later.

Best practice: Have at least one backup supplier in case you run into problems with your primary supplier. For example there will be delays. This is virtually guaranteed to happen and you don’t want to lose business especially during your peak sales period.

Volumes

Ask for quotation based on various levels. For example you can request based on the following three quantities: Minimum order quantity (MOQ), your expected first order size, and the best case scenario if your sales are explode.

For example 50pcs, 500pcs, 5000pcs. This way you can plan for an initial trial order and at the same time gauge the price spread as well as milestones to aim for to get better pricing. This also shows the supplier that you are serious about doing business.

4) Due Diligence – Online research

When reviewing pay attention to the supplier’s Product mix. This will be a clue whether this product is their strength, an ancillary product, or even if they are a trading company.

Is the product you’re looking for the primary product they offer? If you are looking for speakers and you see them listing of 60 variations of an unrelated product iPhone cases then most likely they are a trading company getting it from somewhere else.

Factory information – Keep in mind that this is normally self-reported so take it with a grain of salt

Factory photos – Good for a general idea but don’t trust it 100%. Copying and Photoshopping is all fair game here.

Contact information – Do they reply to emails? Do their telephone numbers work?

Company registration/Business license, registered capital – this is nice to know but not a deal breaker in my opinion.

Certification: It’s common knowledge that in China many types of quality management certifications for example ISO-9001, is easily bought. Despite Xi Jinping’s best efforts, corruption is still here. So take these certificates with a grain of sale. There’s a saying ????? ti?n g?o huáng dì yu?n which means the Sky is high and the emperor is far away. This means that there are limits to the reach of the government.

Gold supplier certification – This is purchased by the supplier and one of Alibaba’s revenue streams. To be fair, Alibaba does attempt to verify the factory’s information but I wouldn’t rely on just that.

Website – Don’t judge a book by its cover. Even a college student can put together a good-looking website. Trading companies are great at this. On the other hand, many legitimate factories don’t even have a website nor are they found on Alibaba.. They may not even have a person that speaks English! Take the website with a grain of salt and do your homework.

5) Samples

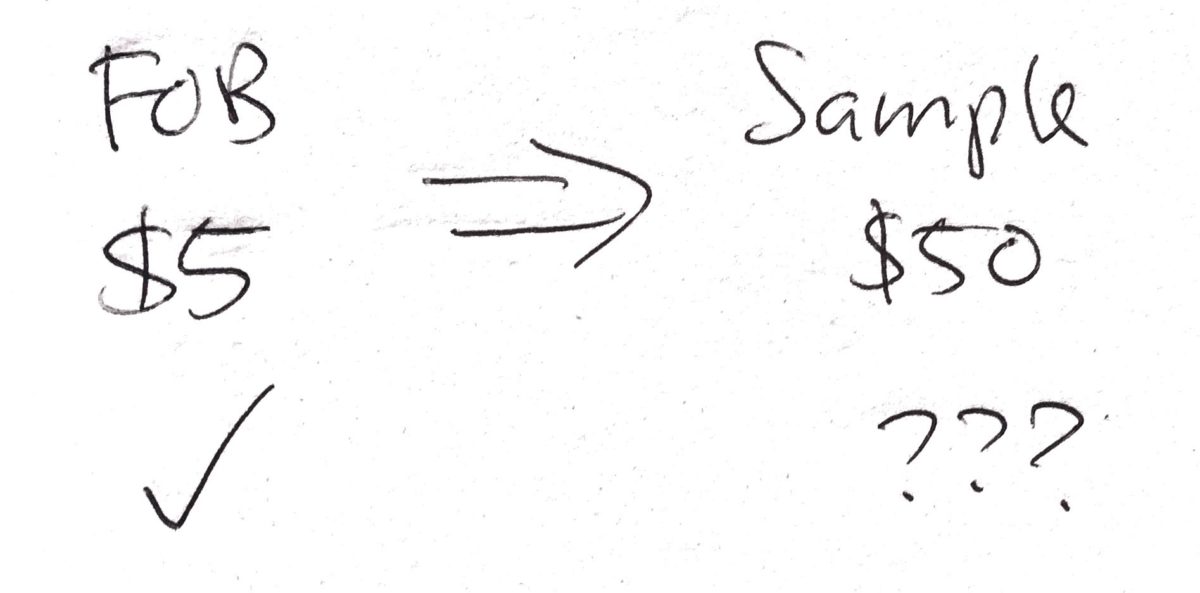

After you have a good feel for the supplier and have decided on an agreeable product specification and initial pricing now it’s time to request a sample. Some people take a leap of faith and don’t request a sample before placing an order so it depends on your risk tolerance, time constraints, and budget.

If you do decide to request a sample, you will need to workout the payment and shipping method. Normally for a small and lightweight widget you can ask the supplier to ship it by Fedex or DHL for most countries. For low value items, the supplier may even waive this cost and only charge you shipping.

6) Receive sample, evaluate and modifications if needed. If OK then proceed.

7) Purchase Order

Place a purchase order to the seller to clarify the product specifications, quantities, price, and terms.

8) Payments

Payment terms:

When placing orders with a new supplier, never pay 100% upfront. The only exception would be for small samples orders where the amount is not significant.

There is no industry standard but 30% advance payment and 70% due upon shipment after inspection is usually fair. Some suppliers request 50% advance and 50% before shipment for initial orders. You should negotiate better terms as you strengthen your relationship.

Payment method:

Bank transfer is typical for large orders. Paypal is also common especially for small orders and this would work for credit card holders. In all my years I’ve never used Western Union.

Dirty trick: Make sure that the beneficiary’s name matches the registered company name. If it does not that’s a definite red flag and many have been scammed this way where the money ends up in a 3rd party’s account.

9) Shipment

Quality Inspection – The factory informs you that your order is ready for delivery. Do you trust them to ship? This depends on your appetite for risk, the complexity of the product, and your relationship with the supplier.

For low value total orders, you can ask the supplier to send a self-inspection report with photos. Of course you would indicate the inspection criteria and be as detailed as possible with measurements, pictures, and accepted quality levels (AQLs).

For medium to larger-sized orders, I suggest hiring a 3rd party inspection agency. Asia inspection is affordable and sufficient for most simple product inspections. They start at $309 per man-day. For inspections that require a higher degree of technical expertise you can consider larger inspection agencies such as Bureau Vertitas and SGS at a higher cost. After the inspection and if the products pass inspection then you will pay the remaining balance and have them ship the product.

Dirty trick: Corruption is very rampant in the quality inspection realm. Kickbacks to inspection agents from suppliers are very common. There’s a saying that many multinational firms have become too “localised”.

BONUS: Advanced tactics to test whether a supplier is an A-player, mediocre, or a scam:

- Request a sample – and evaluate the quality. While you are doing this you will be benchmarking their responsiveness, attitude, and service. Think of it as a first date. How do they look? How do they behave? Are their values similar to yours? If you’re serious about sourcing, look to build long term relationships. This is win-win as forward thinking suppliers would rather invest in a reliable long term partner rather than have to constantly go fishing for new leads. After reviewing the sample, give the supplier your feedback and corrective action plans and see how do they react?

- Factory Visit – If you are serious about doing business with this supplier I strongly recommend visiting the factory yourself or hiring someone to do so. This is a chance to see how things work and how things are made, meet with management and begin to build a relationship, as well as see if things add up.This also shows that you are putting some skin in the game and are serious about doing business. If you put yourself in the factory owner’s shoes, making the effort to visit the factory separates you from your competitors in that you are serious about doing business and not just window shopping for RFQs on Alibaba. After the meeting if you can have lunch with the supplier definitely do so. This is a chance to build “guan xi” e.g. building relationships and even friendship with the factory staff. The Chinese are normally very friendly and will be curious to learn about you and your country. But watch out for drinking and toasting though. But that is beyond the scope of this article.

Red flags

- Factory does not manufacture the product you are looking for. Sounds obvious but you hear excuses such as we had a large order of widget B so we don’t have any widget A on the assembly line. But I can show you widget A in our showroom. This doesn’t mean anything. Dishonest suppliers will event take products from competitors, other client samples, or even buy them elsewhere and put them in their showroom claiming they made it. If you visit the factory and don’t see the raw materials, equipment, and production to product widget A then don’t believe it.

- Is the factory busy, slow, or empty? Unless you are in immediately before or after a major Chinese holiday (insert Chinese holiday calendar) an empty factory is not a good sign. They may be in dire straits and have laid off their workers. Or they may be new. Or they may be shutting down. Don’t expect them to seamlessly onramp after you place an order. Also don’t bear the risk for their learning curve if they’ve never produced this product before. Good factories have busy workers and a palpable buzz in the air.

To get more sourcing secrets and best practices, please signup for my free newsletter.