Recently I listened to an interesting podcast from Scott Voelker aka “The Amazon Seller”. He shared a story about a quality problem with one of his Amazon products which led to a SUSPENSION. The problem was with with his bundled product. Apparently “some of his products were missing pieces and the customers were returning them”. Well Amazon noticed the unusually high return rate so they SUSPENDED his listing! This meant ALL HIS SALES STOPPED on this listing. Scott was smart to take action and file for a removal order to take back the defective inventory to fix it. Obviously he wasn’t going to ship them back to China (too expensive and time consuming) so he decided to fix them himself. Meanwhile he switched the listing from FBA to merchant fulfilled (different selling option) to start selling the product again.

But in the process HE LOST A TON OF SALES from the time the listing was down to when he fixed the problem and shipped them back to Amazon. And he had to spend his own time and hard-earned money to fix the problem. This took away time he could have spent growing his business or being with his family. Furthermore it’s important to note that merchant-fulfilled listings generate much lower sales than FBA. Many Amazon Prime members only buy Prime fulfilled listings so he lost out on these sales opportunities.

Now I don’t mean to bash Scott and he’s quite an expert on selling on Amazon FBA and he’s a great teacher who’s given a lot to the Amazon seller community. But like the rest of us, nobody is perfect and we all make mistakes. So the important thing to ask is: “What can we learn from this? What could Scott have done to prevent this nightmare?”

What if he could have detected these problems early-on before the order left the factory? If so, he could have asked his supplier to fix problems BEFORE THEY SHIPPED. And at AT THEIR COST. This would have meant:

- No customer complaints and returns leading to a suspension

- Not having to ship products from Amazon back to his house and then back to Amazon FBA

- Not having to spend time (and money) to fix the problem himself

- No lost sales

I think Scott would be a happy camper!

How do we do this? Rather than flying blind and taking a risk on every shipment, experienced sellers and importers inspect their products BEFORE they leave the factory. It’s called a pre-shipment inspection. And it’s a small price to pay for the amount of time, money and headaches it can prevent. Benjamin Franklin once said “An ounce of prevention is worth a pound of cure.” So I’d like to share with you how I arrange pre-shipment inspections to reduce quality problems, lower the risk getting suspended by Amazon, and save you time and money so you can focus on growing your business.

First off, here are some of the main BENEFITS of arranging a pre-shipment inspection:

- Catch quality problems early on so you don’t have to deal with defects after products land in the US

By catching problems before they leave the factory, you can have the factory FIX THEM at their expense! Sure it may take a little longer to ship but you will be getting peace-of-mind and better quality product. On the other hand, if you waited until the products landed in the US (e.g. ship it to your house) then my question is, how will you fix any problems that arise?I recently met an Amazon seller from Romania who sold on Amazon’s US platform. He told me about a problem he had with a shipment from China. Since he didn’t live in the US he has his supplier ship the products to his a friend in the US who would inspect it before shipping to Amazon’s warehouses. Well after the product arrived in the US they discovered problems. After emailing back and forth with Chinese factory, they was cooperative and agreed to replace these defective products and ship them to the US. But the seller lost significant time going back and forth with the supplier to solve this problem not to mention the opportunity cost – lost sales. I estimate this process would take at least two to three months for communication, production, and re-shipment resulting in at least tens of thousands of dollars in lost sales!If on the other hand, he hired a 3rd party inspection agency to check the order and fix the problem before it left the factory, he probably could have avoided the problem and have less headaches and more sales.

- Lower your return rates and risk of Amazon suspension

If you ship direct to Amazon WITHOUT an inspection and discover problems later (like Scott did), then you will definitely get negative customer feedback, deal with many returns, and possibly face an account suspension. You can significantly lower your risk by a arranging a simple pre-shipment inspection.

- Keeps the supplier on their toes – get better quality product

Many times, simply letting the factory know that you plan to arrange an inspection before shipment will keep them on their toes. This means they will pay more attention to your order production because they know you are serious about quality. Some experienced importers tell factories they will inspect even if they don’t follow through to arrange an inspection! While I don’t necessarily agree with this, it does work from time to time.

- Allows you to ship product from the factory straight to Amazon (and not to your house) to start selling sooner and reduce shipping costs

It doesn’t take a genius to figure out that shipping from point A (China factory) to point B (Amazon FBA warehouse) is faster and cheaper than point A (China factory) to point B (Your house in the US) and then to point C (Amazon FBA warehouse). Also I would much rather have the factory handle problems in China (lower cost of labor, no additional shipping times) than handling this in the US (high cost of labor, emails back and forth with factory to resolve the problem, shipping times of replacements from China to US, etc).

By now you’re probably asking WHEN should I arrange an inspection? Is a pre-shipment inspection necessary for every order?

As a general rule of the thumb the more complex the item, the newer the item (i.e. first production run), and the newer the supplier the greater the risk of problems. Thus the greater the need for inspection to lower your risks. Another key reason to inspect is if you are aware of a common defect with your product. For example if one of your products scratches easily and you are aware of this problem based on past order history then it makes sense to arrange a pre-shipment inspection because “history repeats itself.”

I like to think of a pre-shipment inspection as a safety net to lower your risk. This will help you identify these problems before shipment while they can be more easily and cheaply fixed.

Here’s an overview as to when to arrange a pre-shipment inspection:

- Expensive products or high order values: In these cases it makes sense because the cost of inspection is lower on a order value basis. For example for a $30,000 shipment a $300 inspection amounts to only a 1% cost while for a $3,000 shipment this amounts to 10%! It makes more sense to inspect when you have shipments with larger order values.

- Highly complex items: I’m more likely to inspect items that are more complex with more moving parts such as electronics. In other words products where things are more likely to go wrong.

- Fragile items: Anything easily breakable or scratched such as glass. I make sure to have them inspect not only product but also PACKAGING. Chinese suppliers often times package their product improperly which causes damage DURING SHIPMENT. So make sure there’s enough protection around the product to reduce risk of damage during transit. This is especially true for sea shipments because imagine your product being on a ship for a month. Boxes move around and product gets damaged if not packaged properly.

- New items: If the factory is making this for the first time, then expect mistakes. This is an especially important time to arrange inspections to catch these problems early.

- New Suppliers: Just as in a first date when you are getting to know each other, if this is your first time working with a supplier there will be some bumps in the road. You’re more likely to have miscommunication, and misaligned quality expectations when first working together. Over time, as the relationship develops and as you learn each others’ preferences, likes, and dislikes, these “bumps in the road” will smooth themselves out.

- Common defects you are aware of: If in a prior shipment you had problems then you should instruct the inspector to pay special attention to these problem areas. For example with one of our products, the first batch of product had loose screws. So in the next batch we made sure to have the screws inspected. So it makes sense to not only inform the supplier to make a corrective action plan but also for you to take the initiative to inspect for this problem in the next order.

EXCEPTIONS: When can you choose NOT to inspect? Do I need to inspect 100% of orders?

In a perfect world, inspecting 100% of all orders would be the ideal way to eliminate risk but this is not feasible. We are in the real world we all have budget constraints and limited cash flow. And we are running against the clock and want to get the product for sale to our customers. So here are some of my insights. Do take this with a grain of salt as these are general rules and your mileage may vary depending on your product, tolerance for risk, and your aggressiveness.

- Simple products: One instance where we did not arrange pre-shipment inspections is if the product is very simple with a low likelihood of any critical problems. If it’s a simple metal and rubber auto part there’s a lower chance of things going wrong than if it was a tablet computer

- Wide range of quality tolerance that is difficult to define: Another instance is if you’re more tolerant to what is defined as acceptable product. For example one of our clients who sourced auto parts from China did not want to arrange pre-shipment inspections because they felt it’s likely that all of the orders would be “FAILED” according to the inspection agencies standards. It was a low cost metal and rubber auto part. So the client is willing to tolerate a certain degree of difference that is difficult to define on paper to an inspector. In this case they decided that an inspection would not be worthwhile. Over the years of importing numbers containers of product per month, were instances of defective product (which the supplier replaced at their cost) but over the long haul this strategy saved him money.

- Small orders: If you’re making a small order then the cost of an inspection may not be worthwhile. For an order of $1,000 you probably wouldn’t want to spend the $300 to hire an inspection agency. This would be 30% of the order value. What would I do instead? I would ask the factory to make a self-inspection and send me the report. Or I would ask them to ship me pre-production samples

HOW to arrange a third party pre-shipment inspection?

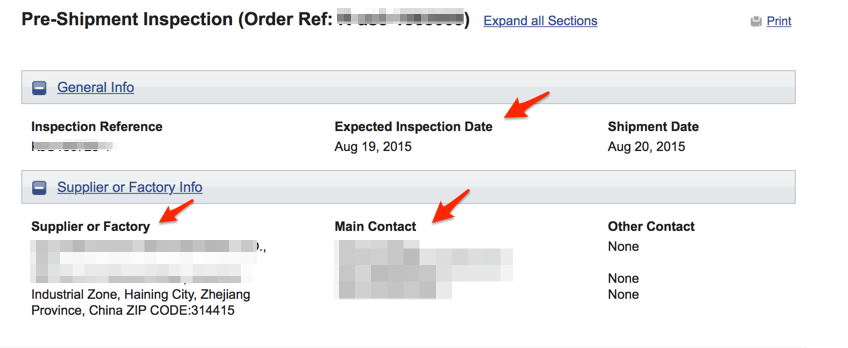

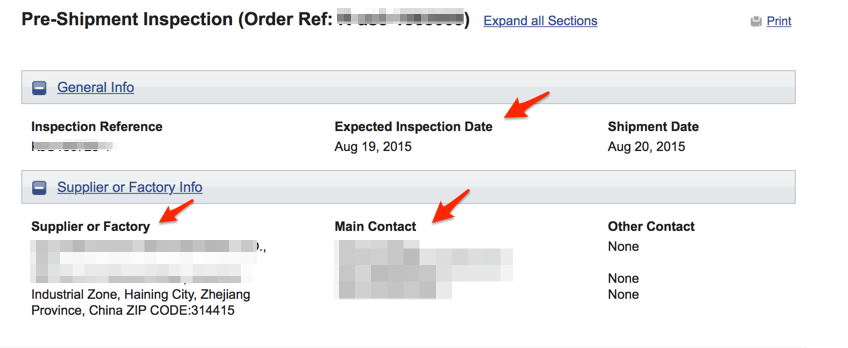

I’ve outlined the three main parts to a pre-shipment inspection. These include the supplier’s factory information, expected inspection date, your product name and specifications, and inspection details. Here is a sample pre-shipment inspection checklist using solar vacuum tubes as a reference.

- Supplier’s factory information:

- Factory address: both English and Chinese

- Contact person’s name, telephone, and email

- Date of your scheduled inspection

- Date of shipment

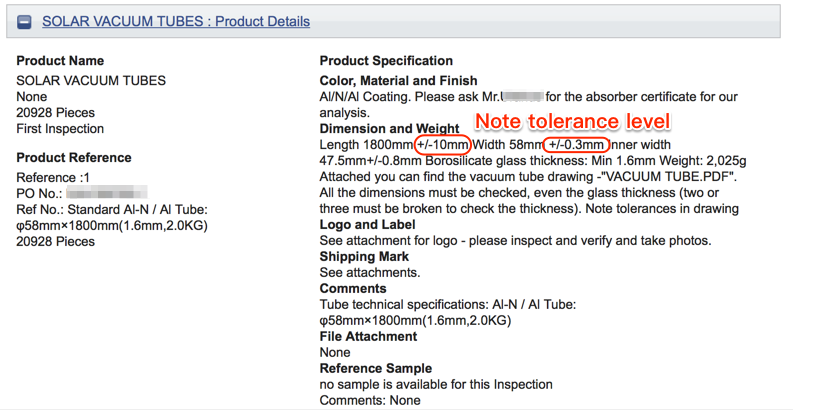

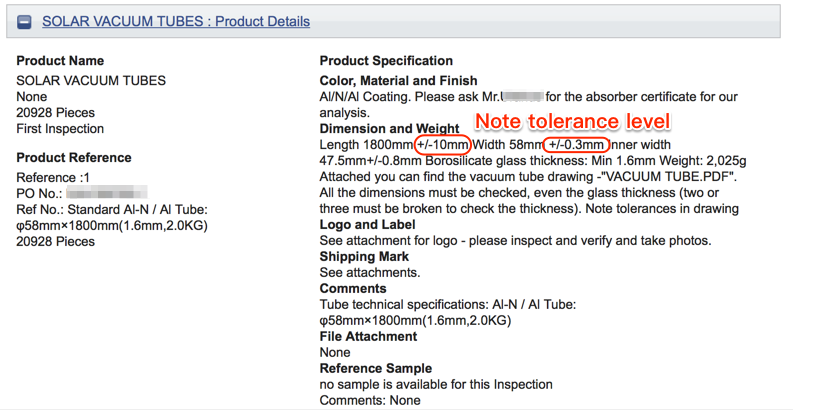

- Product Name and Specifications: Be as specific as possible. Put yourself in the shoes of the inspector. The more reputable inspection agencies will have internal checklists based on product categories that you can use if you’re not sure what to inspect.

- Color, Material, Finish: List your product specifications which include pictures, measurements, material, packaging requirements, your logo, UPC barcodes and any other details that you want to check.

- Dimensions and weight: Note the accepted tolerance levels that you can accept. For example if the tube is 1.80m long and you can accept a length between 1.79m to 1.91m or “+/- 10mm.” (see picture below). You might ask why should I accept any tolerance, I want the product to be EXACT. Well in the real world, nobody is perfect especially factories so you should decide upon an accepted tolerance limit and note this in your purchase order (before production begins).

- Logo and labels: Important for private labelers.

- Additional comments

- Reference sample: Optional but you can provide a sample to the inspector as a reference.

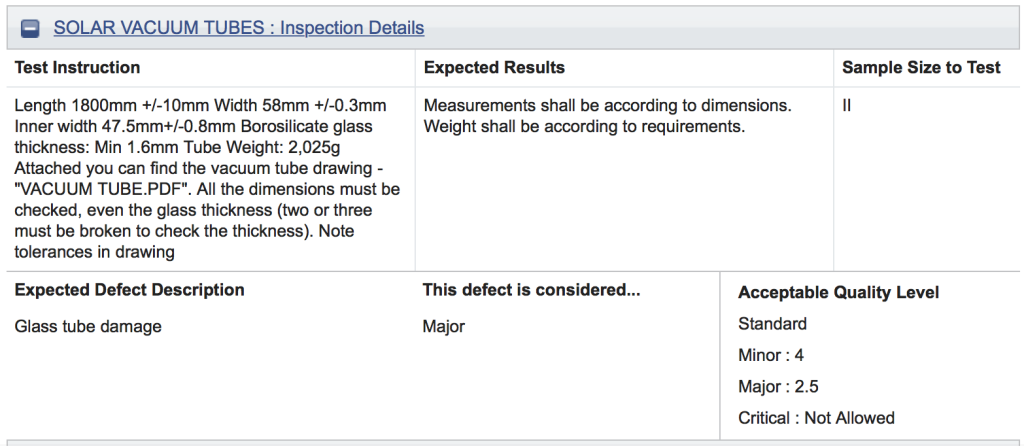

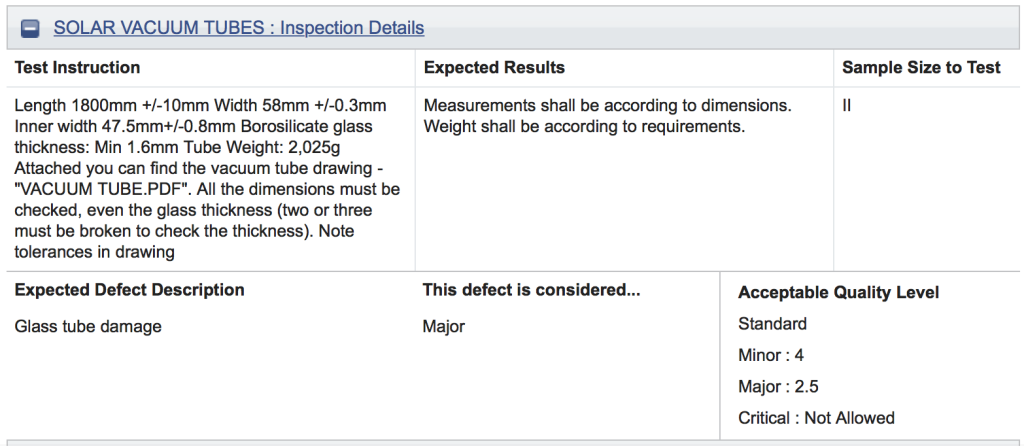

- Inspection details: Make sure to list the most common expected problems with your product.

- Test instructions: If you have any specific instructions, note them here. If not, the inspection agency will have a pre-determined checklist based on your product category and you can use that. This depends on your exact product so consult your inspection agency.

- Expected results: What you expect for the product to pass inspection.

- Sample size to test: I recommend you follow the inspection agency’s suggestion.

- Expected defect description: Describe your expected defect. For example: “Glass tube damage”.

- Defect is considered: Three main types of defects: Critical, Major, and Minor. I recommend you follow the inspection agencies standards if you are new to this.

- Accepted Quality Level (AQL): Think of this as the upper limits of defects that are allowed. If they find a larger proportion of defective items, then the inspection will result in a “FAIL”. A common AQL is Minor: 4%, Major: 2.5%, Critical: Not allowed (See picture below). Your inspection agency will have these options for you to choose from.

HIRE an inspection agency

I normally budget around $300 per day for inspection. If cost is a concern and you have a larger number of units in your order you can reduce the sample size to one man-day. Of course a smaller sample size may miss some problems. But that is the tradeoff.

In terms of inspection agency recommendations: I’ve used Asia Inspection over the years with good results. The major players in the inspection agency game include multinationals SGS and Bureau Veritas though they may be more expensive.

WAIT for the results

Normally I expect to receive results within 24 hours of inspection. Based on this you will either (a) approve the lot for shipment or (b) reject and/or work with the supplier to fix the problems.

IF PASSED then I review the report details and note any minor defects and then green-light the shipment.

If they “FAIL” the inspection then it’s purely the buyer’s (YOU) decision whether to accept the shipment because they have been forewarned.

Common reasons inspections FAIL:

Besides quality problems, another reason an inspection may be wrongfully “FAIL” an inspection is due to miscommunications in the Quality Control criteria. So make sure to double check all the measurements, pictures, packaging, and any other common problems in production.

In my years of sourcing from China, I’ve noticed a common trend. When in doubt, the inspection agency would rather FAIL the inspection to protect themselves than approve it. In other words, if they “PASS” a shipment that has problems discovered later then the inspection agency can be held responsible. If they FAIL a shipment and the buyer agrees to ship it, then it’s purely the buyer’s responsibility in making this decision.

What to do if your pre-shipment inspection fails?

- Look carefully at the details of the inspection report. Are the reasons it failed enough to refuse shipment? Sometimes if it’s a “minor” defect you should ask yourself if this is acceptable to your customers. Steve Jobs was famous for saying “real artists ship” which means that it’s more important to actually deliver than delaying a launch trying to make the “perfect product”.

- Show the report to the factory and ask them for a corrective action plan to fix critical problems.

- Then depending on the outcome and who’s at fault, arrange a re-inspection. I recommend hiring at least a different inspector (or agency) to prevent any “buddy-buddy” relationships from forming. (See “BEWARE FRAUD” below)

- Decide whether or not to accept shipment.

- If or when placing a re-order later, emphasize the problems and the corrective action plan in the purchase order.

- BEST PRACTICE: If the first inspection fails and the factory was at fault, you should negotiate to have the supplier pay for re-inspection. This will save you $300.

Poor man’s pre-shipment inspection: If you want save money and are willing to take a risk

If you choose not to hire a third party inspection agency, the least you can do is to ask the supplier to self-inspect the order and send you an inspection report. Clearly this will option is not as comprehensive as a third party inspection nor will it come from an unbiased source, but it’s better than nothing. Remember pictures are worth a thousand words and you may be able to spot some problems. This is how I would do it:

- Ask the supplier to take pictures of the product, the instruction manual and any inserts, and packaging. For product and packaging, ask for pictures from different angles.

- Ask them to take measurements and weights (if applicable)

- Ask them to test it based on common problems that occur

- Optional: If you have a sourcing agent or trusted person in China, ask your supplier to send a few units of actual product to them for inspection.

BEWARE FRAUD

Sourcing in China is a dirty business. Sure there are honest guys out there but there are so many moving parts that can go wrong that it’s hard to keep track of them all. Kickbacks and bribes are not uncommon. Third party inspection agencies (both big multinationals and smaller agencies) are not immune to this.

So I’m not surprised when newbies report that their factories tell them that the third party inspection agents asked for a “tip” or else face a failed inspection report. It happens everyday in China. So what can you do? At the end of the day, I take the inspection agency’s recommendation with a grain of salt. Their decision is one factor but I always look at the DETAILS of the inspection report. Ask yourself WHY was it failed and do these problems matter to me and my customers? Ultimately you are the CEO and it’s YOUR DECISION whether or not to accept the shipment.

In summary, pre-shipment inspections are an excellent way to reduce your risk of quality problems which can lead to high customer returns and even an Amazon account suspension. Regardless whether you hire a third party to inspect or have the factory self inspect, the important thing is to try to catch problems BEFORE the product leaves the factory floor. This way they can fix it at their expense and this will save you a lot of time and headaches down the line.

If you’d like to get a pre-shipment inspection worksheet which you can use before your next shipment, please signup for my free newsletter.